Precision Automotive Equipment brings Vamag down under

Precision Automotive Equipment has partnered with one of the world’s leading workshop equipment manufacturers, Vamag, to supply premium quality roller brake testing equipment to Australian and New Zealand automotive repairer shops and service centres.

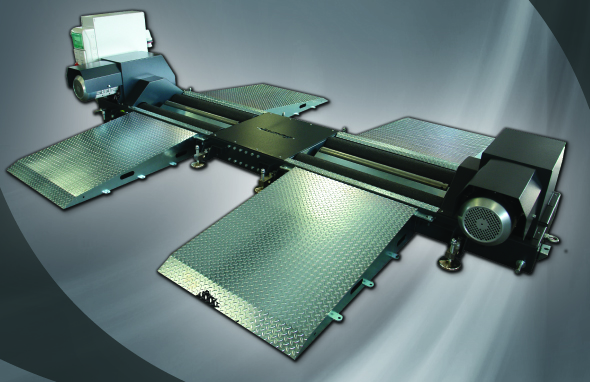

The company will initially offer three types of roller brake testing machines, including a portable (above ground) unit, an in-ground flat-bed variant and an in-ground raising-bed model.

All Vamag roller brake testers feature soft start 2WD or 4WD bi-directional capability, an integrated weighing system with eight load cells for static and dynamic weight measurement, and provision for load simulating via the installation of an accessory kit. They also include, as standard equipment, a PC tower and computer cabinetry, along with a full Windows Operating System based tablet.

Precision Automotive Equipment said all Vamag roller brake testing machines comply to NHVR testing standards, ensuring that Australian and New Zealand automotive workshops can perform brake testing procedures accurately and safely.

The company also offers hydraulic multi-movement play detectors with the Vamag in-ground and portable roller brake tester models, completing all requirements to safely test vehicle suspension componentry within a controlled automotive workshop environment.

Vamag is an Italian family business with more than 60 employees and three manufacturing facilities located across the country. Vamag has more than four decades of experience producing 100 per cent Italian-made, premium quality, electronic automotive testing equipment that is used in automotive workshops all over the world.

The key to Vamag’s ongoing success is its development of functional, leading-edge technology and the company’s attention to detail. A key advantage is that Vamag has complete control of every facet of its in-house manufacturing and technology development.